Bearings

Built-in bearings

What are built-in bearings?

Built-in bearings, are specially designed bearings placed in a bearing housing. They provide stable and durable support for rotating shafts in a variety of machines. Think of applications in agriculture, food industry, conveyor belts and more.

What characterises the seals of built-in bearings?

Built-in bearings are fitted with a sliding seal on both sides. This is a pressed steel plate on which a rubber lip seal has been vulcanized and in which the rubber lip runs over the cylindrical surface of the inner ring. Additional sheet steel rings are fitted on the outside of the inner ring. These are the pendulum discs. This combination gives you a double-acting seal and thus excellent protection against dirt, corrosion and damage.

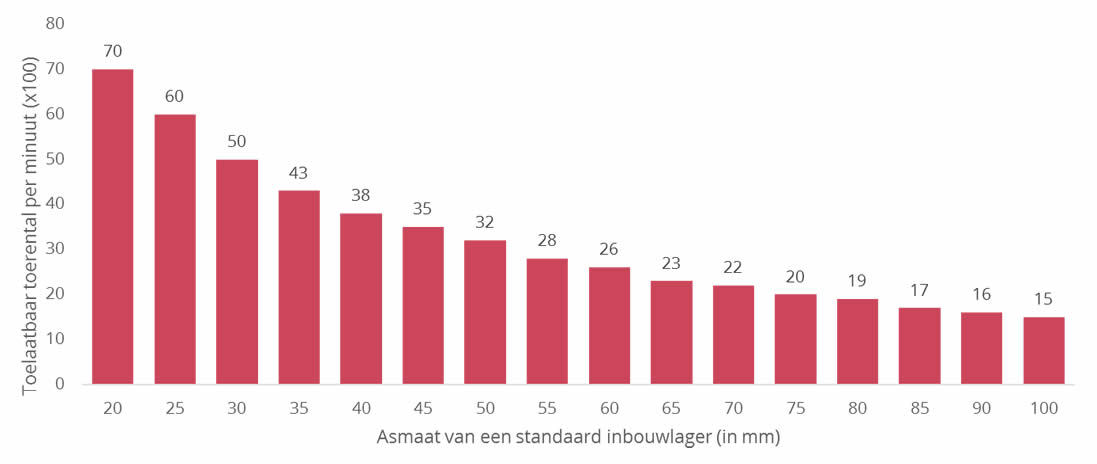

What are the permissible speeds of built in bearings?

The maximum speeds of built-in bearings depend on several factors:

- Diameter of bearing bore

- Heat generation from seal friction

- External temperature influences

- Grease filling and fixing method on the shaft

In heavy or demanding applications, you should always count on lower maximum speeds.

Chart: Permissible speed by shaft size

When should i lubricate built-in bearings?

As standard, all recessed bearings are supplied with an optimum amount of litium soap grease and are suitable for temperatures between -20°C and +100°C. Under normal conditions, relubrication is not necessary. But in dirty or humid environments, regular lubrication is recommended.

TIP: Use the included grease nipple, and make sure the grease groove lines up with this nipple for proper grease distribution.

Guidelines for relubrication intervals

The frequency of relubrication depends on the operating environment and temperature.

| Bearing operating temperature | Clean | Dirty | Dirty & moist |

|---|---|---|---|

| 50 degrees Celsius | 3 years | 6 months | 3 months |

| 70 degrees Celsius | 1 years | 2 months | 1 month |

| 100 degrees Celsius | 3 months | 2 weeks | 1 week |

TIP: Preferably lubricate during operation, this ensures immediate and good grease distribution without damage to the seals. Do not use excessive grease pressure, to prevent leakage or damage.

Why choose our recessed bearings?

- Durable and low maintenance

- High-quality seals against dirt and moisture

- Widely applicable to all industries

- Easy to assemble and relubricate

Need recessed bearings?

View our range of various types and sizes of flush-mounted bearings, available directly from stock through our webshop.