Bearings

Lifespan of bearings

The life of a bearing is defined as the number of rotations or operating hours at constant speed until the first signs of material fatigue occur. Although identical bearings can achieve different life spans under the same conditions, an accurate calculation can help predict and optimize life.

Factors affecting bearing lifespan

To achieve maximum bearing life, several factors must be considered:

- Dynamic load rating: the maximum load that a bearing can tolerate at a specific lifespan.

- Load and speed: higher loads and speeds reduce the lifespan.

- Shaft and housing fits: incorrect fits can cause premature wear.

- Component alignment: misalignment leads to additional stress on the bearing.

- Operating temperature: high temperatures can degrade the lubricant and shorten its lifespan.

How do you calculate the lifespan of a bearing?

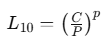

The ISO 281 standard provides a methodology for calculating the lifespan of a bearing. The basic formula is:

In which:

- L10 = expected life in million rotations (90% of bearings achieve this life)

- C = dynamic carrier number

- P = equivalent load

- p = life exponent (3 for ball bearings, 10/3 for roller bearings)

This calculation can be adjusted with correction factors such as lubrication, temperature and material fatigue.

The importance of correct shaft and housing fits

The fit between the bearing and the shaft or bearing housing is critical for a long life. ISO tolerances determine the proper fit based on:

- Tolerance fields: defined relative to the zero line and denoted by letters (large letters for houses, small letters for axes).

- Rotation ratio: how the inner or outer ring moves relative to the load.

Types of loads and effect on the fit

| Load type | Description |

|---|---|

| Rotary load | The ring is stationary and the load rotates, or vice versa |

| Stagnant load | The ring and load do not move or rotate synchronously |

| Undetermined load | The load varies in direction, for example, due to vibration |

The choice of fit depends heavily on these factors. An incorrect fit can result in bearing damage due to slippage or excessive stress.

Other factors affecting longevity

In addition to load and fit, there are additional factors that come into play:

- Material expansion: aluminum expands more with heat than steel, which affects fit.

- Thin-walled housings and hollow shafts: may affect bearing stability.

- Vibrations and shocks: can vary the direction of the load, requiring a flexible fit.